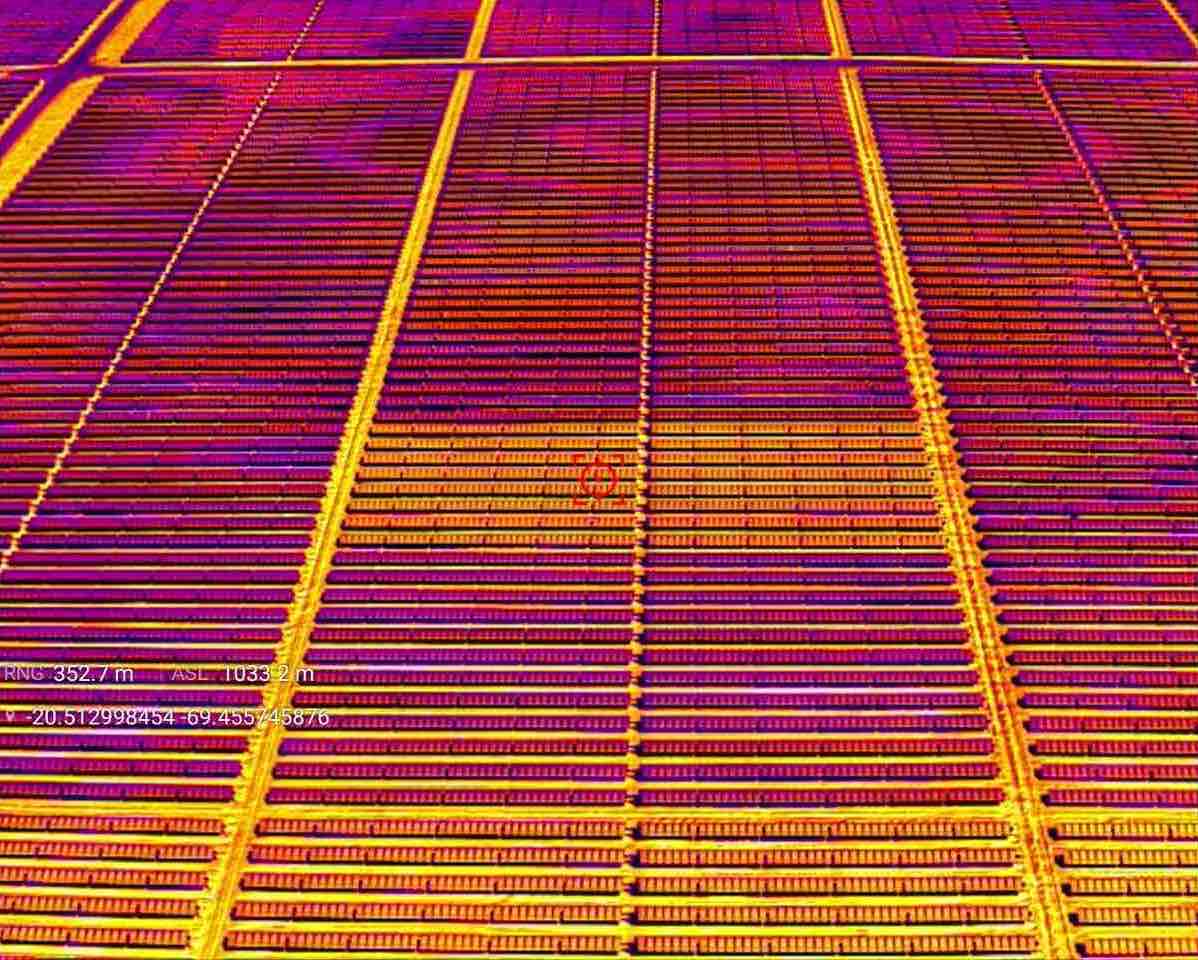

Thermal aerial survey drones have become an essential tool for the maintenance and monitoring of photovoltaic (PV) plants. These drones are equipped with thermal cameras that can detect hot spots and other issues within the PV panels that can cause power loss and damage. In this blog post, we will discuss some best practices for using thermal aerial survey drones to ensure that you are getting the most accurate and useful data possible for your PV plant.

- Choose the right drone for the job

When it comes to thermal aerial survey drones, not all are created equal. Different drones have different capabilities and limitations, so it is important to choose one that is well-suited for your specific application. For PV plants, you may want to choose a drone with a high-resolution thermal camera, long flight time and payload capacity to carry additional equipment such as LiDAR.

We’re now encouraging our partners to buy their own drones, we diagnose the needs of each customer and recommend the right drone to them as part of our end-to-end service.

2. Perform regular maintenance

Just like any other equipment, thermal aerial survey drones require regular maintenance to ensure that they are operating at peak performance. This includes regular inspections of the drone’s mechanical and electrical components, as well as calibration of the thermal camera. It is also important to keep the drone’s firmware and software up to date to ensure that you are getting the most accurate data possible.

3. Use the right software

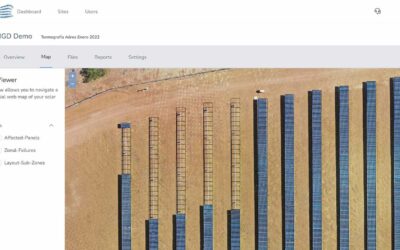

Thermal aerial survey drones typically come with software that is used to control the drone and process the thermal data. It is important to choose software that is well-suited for your specific application. For PV plants, you may want to choose software that can automatically stitch together multiple thermal images to create a larger mosaic, and also software that can create detailed 3D models of the PV plant and panels.

Our open-source software makes the same as proprietary softwares in the market, but you would need someone in your team with the skills to put it on work. Otherwise, you can contact us for a full assestment on how to use our open source software and web service within your company.

4. Plan your flights carefully

Proper planning is key to getting the most accurate and useful data from your thermal aerial survey drone. This includes carefully selecting the best time of day to perform the survey, as well as selecting the best flight path to ensure that the drone is able to capture the data you need. It is also important to take into account any potential obstacles that the drone may encounter during the flight, such as power lines or buildings.

For PV Plants we have developed a highly precise guidance and checklist that you could use in order to flight your assets in a right way: Data Collection Guidance

5. Use the right temperature range

Thermal cameras have different temperature ranges. It is important to select the right temperature range for your application. For PV plants, you may want to choose a camera with a higher temperature range so that you can detect even small temperature changes within the PV panels that can cause power loss and damage.

6. Check the weather

The weather can have a significant impact on the quality of the thermal data that you collect. It is important to check the forecast before you perform a thermal aerial survey. For example, if it is a hot and sunny day, the thermal data may be affected by solar radiation, which can make it difficult to detect temperature changes. On the other hand, if it is a cold and cloudy day, the thermal data may be affected by atmospheric absorption, which can make it difficult to detect temperature changes.

7. Use additional sensors

A thermal camera is not the only sensor that can be useful in PV plants. Additional sensors such as LiDAR, multispectral cameras, and RGB cameras can provide additional information on the condition of the PV panels, as well as the surrounding area. This additional data can be used to create detailed 3D models of the PV plant, and also to detect issues such as shading and vegetation growth.

8. Perform regular surveys

Regular surveys are essential to identify issues early and prevent major problems from occurring. Scheduling regular thermal aerial surveys of your PV plant can help you identify potential issues before they become major problems, which can save you time, money and avoid power loss.

0 Comments